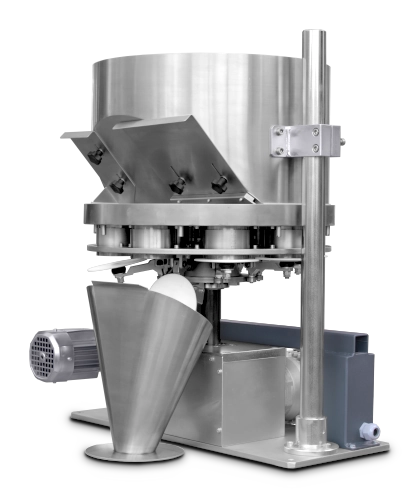

Accurate volumetric dosing

Volumetric fillers are used for dosing small loose products, abrasive and not dusty products such as granulated sugar, salt, rice, peas, lentils, coffee, poppy seeds, some types of pasta such as rigatoni, shells and other goods such as compound feed, granulates, etc.

A lot of types ...

... flap filler, slide filler, friction filler, etc.

This filling device is standard developed especially as the filling device for packaging machine of MH type, in which case the control of filler is provided by the packaging machine.

It can be used also as an independent filling device with outside control panel, or it can be adjusted as the filling device for packaging machine of another producer, or other construction.

For filling of the feeding hopper is optimal to use feeding conveyor VD1.

Technical parameters

| Flap volumetric filler | Volumetric fillers | ||||

| Filler type | KL1 | MD2 | MD3 | DS1 | DS2 |

| Output* | up to 110 doses/min. | up to 60 doses/min. | up to 80 doses/min. | up to 8 doses/min. | up to 15 doses/min. |

| Dose volume | 800 ml - 7000 ml | 35 ml - 1500 ml | |||

| Dose volume of one cup | 85 ml - 1840 ml | 80 ml - 960 ml | 150 ml - 3500 ml | ||

| Power supply | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz | 230 V - 50 Hz | 230 V - 50 Hz |

| Power | 370 W | 120 W | 550 W | 50 W | 50 W |

| Noise | up to dB | up to 50 dB | up to 50 dB | ||

| Machine weight | 60 kg | 60 kg | 60 kg | 70 kg | 70 kg |

| Air pressure | 0,6 MPa | 0,6 MPa | |||

| Air consumption at 0,6 MPa | 13,2 l/dose | 13,2 l/dose | |||

| Machine dimensions | H 1180 x W 705 x L 670 mm | H 600 x W 530 x L 650 mm | H 980 x W 704 x L 681 mm | H 900 x W 530 x L 650 mm | H 910 x W 675 x L 1225 mm |

Fillers description

| Flap volumetric filler | Volumetric fillers | ||||

| Filler type | KL1 | MD2 | MD3 | DS1 | DS2 |

| sensor insuring stable level of goods in hopper | ● | ● | ● | ● | ● |

| areas which are in contact with the goods are made of stainless steel | ● | ● | ● | ● | ● |

| supporting frame, set of cups, hopper, dumper, electromechanical drive | ● | ● | ● | ||

| easy and quick exchange of measuring cup | ● | ● | ● | ||

| possibility of emptying of one or more doses at once | ● | ● | ● | ||

| easy to use | ● | ● | ● | ||

| easy cleaning | ● | ● | ● | ||

| small dimensions | ● | ||||

| supporting frame, set of cups, hopper, dumper, electromechanical drive | ● | ● | |||

| easy and quick exchange of measuring cup | ● | ● | |||

| feed-in hopper embedded with retarder | ● | ● | |||

| sensing of limit positions | ● | ● | |||