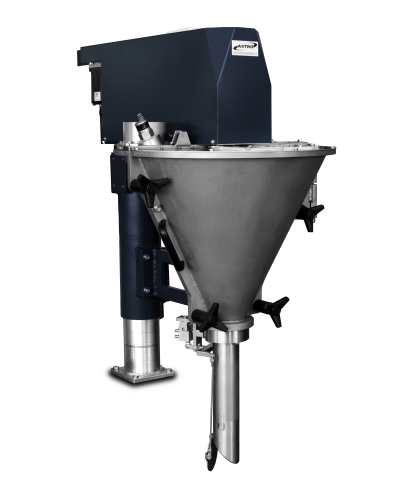

Snegle/snekke fylderen er designet til præcis dosering af støvede, pulveriseret, porous løst gods og nogle granulerede produkter f.eks: formalet kaffe, budding pulver, mel, flormelis, gips, vaskepulver, farve pulver, m.fl.

Denne doserings enhed er standard og udviklet som volumetrisk doseringsenhed til sække maskiner af typen MH.

Doseringspumpen kan mængde justeres til emballeringen og kan anvendes til flere producenters maskiner og eller anlæg.

Til genopfyldning og fyldning af tragt , til optimal ved brugs af tilførselstransportør VD5.

Technical Parameters

| Filler type | SD1bb | SD2bb | SD2bb | SD3bb |

| Output* | to 70 doses/min. | to 110 doses/min. | to 70 doses/min. | to 90 doses/min. |

| Dose volume | 10 ml - 3000 ml | 10 ml - 6000 ml | 1 l - 20 l | 10 ml - 6000 ml |

| Power supply | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz |

| Power | 1,4 kW | 2,8 kW | 3,5 kW | 1,4 kW |

| Noise | to 75 dB | to 75 dB | to 75 dB | to 75 dB |

| Weight | 150 kg | 250 kg | 320 kg | 250 kg |

| Air pressure | 0,4 - 0,6 MPa | 0,4 - 0,6 MPa | 0,4 - 0,6 MPa | 0,4 - 0,6 MPa |

| Air consumption at 0,6 MPa | 0,2 l/dose | 0,2 l/dose | 0,4 l/dose | 0,2 l/dose |

| Machine dimensions | H 940 x W 670 x L 1150 mm | H 970 x W 800 x L 1350 mm | H 1300 x W 870 x L 1450 mm | H 970 x W 800 x L 1350 mm |

| Hopper volume | 10 l | 35 l | 75 l | 35 l |

Description

| Fillers type | SD1bb | SD2bb | SD2bb | SD3bb |

| supporting frame, electromechanical drive, distributor, hopper and tube with screw | ● | ● | ● | ● |

| progressive retardation of screw | ● | ● | ● | ● |

| sensor insuring stable level of goods in hopper | ● | ● | ● | ● |

| mixer ensuring permanent looseness of goods in hopper | ● | ● | ● | ● |

| areas in contact with goods are made in stainless steel | ● | ● | ● | ● |

| split hopper for easy cleaning | ● | ● | ● |

Fillers Advantages

| Filler type | SD1bb | SD2bb | SD2bb | SD3bb |

| adaptive system (self-adjustment of portion) | ● | ● | ● | ● |

| adjustment of portion during operation | ● | ● | ● | ● |

| easy and quick replacement of the tube with auger | ● | ● | ● | ● |

Modifications

| Filler type | SD1bb | SD2bb | SD2bb | SD3bb |

| regulation of revolutions speed of dosing auger | ● | ● | ● | ● |

| different types of closing of auger screw | ● | ● | ● | ● |

| integrated controls of SD2bb with machine MH | ● | ● | ● | ● |