| Technical parameters | |||

| Machine type Number of lanes |

AVSa 1 |

AVSb 1 |

AVSc 1 |

| Output* (doses/min.) | 15 | 15 | 15 |

| Weighing range (g) | 80 - 500 | 80 - 4000 | 80 - 10000 |

| Accuracy | according to standard "e" |

according to standard "e" |

according to standard "e" |

| Volume of weighing bucket (ml) |

to 500 |

to 8000 |

to 13000 |

| Power (W) | 300 | 400 | 400 |

| Power supply | 230 V/50 Hz | 230 V/50 Hz | 230 V/50 Hz |

| Air consumption at 0,6 MPa (l / dose) | 0,1 | 0,1 | 0,1 |

| Weight (kg) | 100 | 120 | 150 |

| Dimensions H x W x L (mm) | 650 x 255 x 1000 |

1100 x 255 x 1700 | 1200 x 255 x 1750 |

* Capacity depends on dose size and kind of goods.

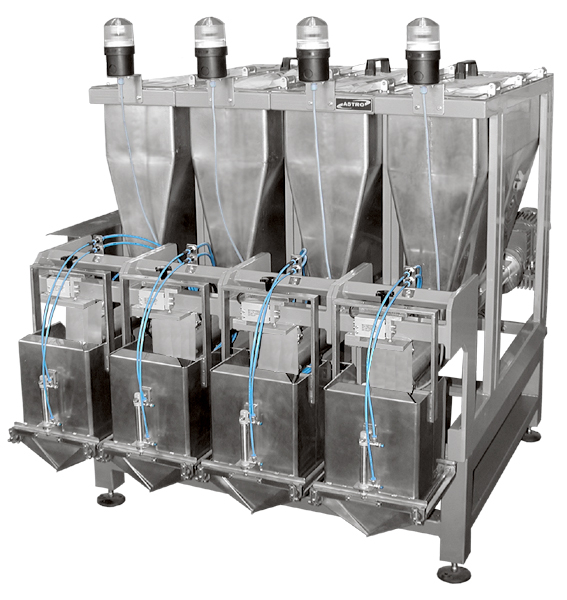

| Description |

| tensometric weighing unit |

| horizontal auger |

| closing the end of the screw |

| display the actual weight in grams |

| monitoring of products level in the hopper |

| areas which are in contact with the goods are made of stainless steel |

| all parts of the machine are protected health harmless surface treatment |

| Advantages |

| 30 memories for different kinds of goods (8 characters for name) |

| automatic state diagnostics |

| automatic weight tarring |

| set of all functions is performed from a mobile control panel |

| 5 international languages for control |

| 2 weighing modes |

| 2 modes of emptying |

| counting of average portion size from previous 20 portions |

| possibility of connection to PC |

| getting higher output rates by adding of supplementary modules |

| Modifications |

| storage hopper and discharge hopper according to customers specification |

| for frozen foods (vegetables, french fries) |

| covering with exhaust outlet |

| separation of abrasion or juices from packaged goods |